DTC B1800/51 Short in Driver Side Squib Circuit |

DTC B1801/51 Open in Driver Side Squib Circuit |

DTC B1802/51 Short to GND in Driver Side Squib Circuit |

DTC B1803/51 Short to B+ in Driver Side Squib Circuit |

for Preparation Click here

DESCRIPTION

- The driver side squib circuit consists of the center airbag sensor assembly, the spiral cable and the steering pad.

- The circuit signals the SRS to deploy when deployment conditions are met.

- These DTCs are recorded when a malfunction is detected in the driver side squib circuit.

| DTC No. | DTC Detecting Condition | Trouble Area |

| B1800/51 |

|

|

| B1801/51 |

|

|

| B1802/51 |

|

|

| B1803/51 |

|

|

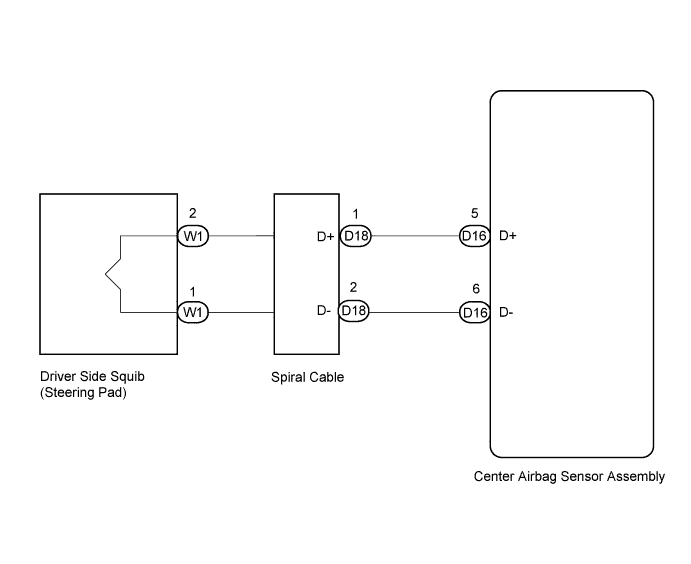

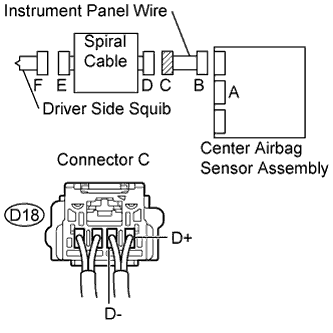

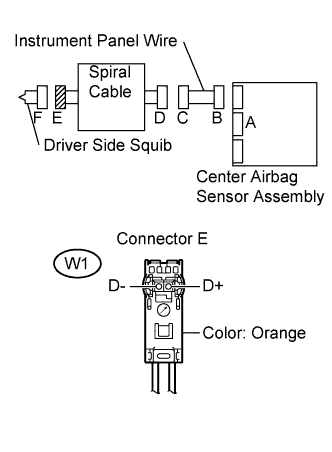

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Perform the simulation method by selecting CHECK MODE (signal check) with the Techstream (Click here).

- After selecting CHECK MODE (signal check), perform the simulation method by wiggling each connector of the airbag system or driving the vehicle on a city or rough road (Click here).

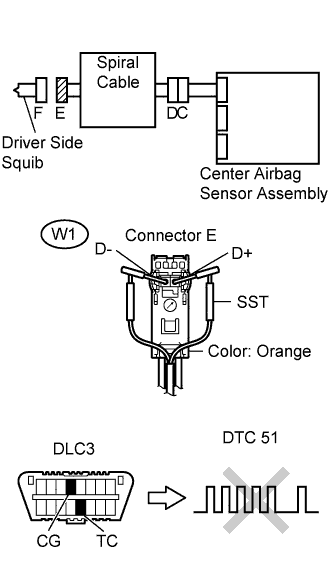

| 1.CHECK STEERING PAD (DRIVER SIDE SQUIB) |

- SST

- 09843-18060

Turn the ignition switch off.

|

Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

Disconnect the connectors from the steering pad.

Connect the white wire side of SST (resistance 2.1 Ω) to connector E (orange connector).

- CAUTION:

- Never connect a tester to the steering pad (driver side squib) for measurement, as this may lead to a serious injury due to airbag deployment.

- NOTICE:

- Do not forcibly insert the SST into the terminals of the connector when connecting.

- Insert the SST straight into the terminals of the connector.

Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

Turn the ignition switch on, and wait for at least 60 seconds.

Clear the DTCs stored in the memory (Click here).

Turn the ignition switch off.

Turn the ignition switch on, and wait for at least 60 seconds.

Check the DTCs (Click here).

- OK:

- DTC B1800, B1801, B1802, B1803 and 51 are not output.

- HINT:

- DTCs other than DTC B1800, B1801, B1802, B1803 and 51 may be output at this time, but they are not related to this check.

|

| ||||

| NG | |

| 2.CHECK CONNECTOR |

Turn the ignition switch off.

Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

Disconnect the SST from connector E.

Check that the spiral cable connectors (on the steering pad side) are not damaged.

- OK:

- The lock button is not disengaged, and the claw of the lock is not deformed or damaged.

|

| ||||

| OK | |

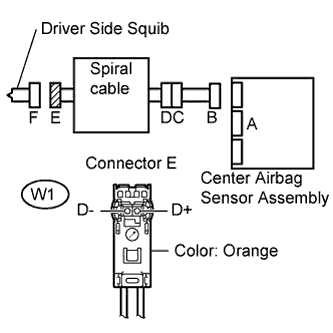

| 3.CHECK DRIVER SIDE SQUIB CIRCUIT |

Disconnect the connectors from the center airbag sensor assembly and steering pad.

|

Check for short to B+ in the circuit.

Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

Turn the ignition switch on

Measure the voltage.

- Standard voltage:

Tester Connection Switch Condition Specified Condition W1-1 (D+) - Body ground Ignition switch ON Below 1 V W1-2 (D-) - Body ground Ignition switch ON Below 1 V

Check for open in the circuit.

Turn the ignition switch off.

Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

Measure the resistance.

- Standard resistance:

Tester Connection Condition Specified Condition W1-1 (D+) - W1-2 (D-) Always Below 1 Ω

Check for short to ground in the circuit.

Measure the resistance.

- Standard resistance:

Tester Connection Condition Specified Condition W1-1 (D+) - Body ground Always 1 MΩ or higher W1-2 (D-) - Body ground Always 1 MΩ or higher

Check for short in the circuit.

Release the activation prevention mechanism built into connector B (Click here).

Measure the resistance.

- Standard resistance:

Tester Connection Condition Specified Condition W1-1 (D+) - W1-2 (D-) Always 1 MΩ or higher

|

| ||||

| OK | |

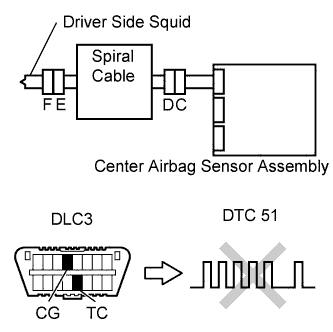

| 4.CHECK CENTER AIRBAG SENSOR ASSEMBLY |

Connect the connectors to the steering pad and the center airbag sensor assembly.

|

Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

Turn the ignition switch on, and wait for at least 60 seconds.

Clear the DTCs stored in the memory (Click here).

Turn the ignition switch off.

Turn the ignition switch on, and wait for at least 60 seconds.

Check the DTCs (Click here).

- OK:

- DTC B1800, B1801, B1802, B1803 and 51 are not output.

- HINT:

- DTCs other than DTC B1800, B1801, B1802, B1803 and 51 may be output at this time, but they are not related to this check.

|

| ||||

| OK | ||

| ||

| 5.CHECK INSTRUMENT PANEL WIRE |

Restore the released activation prevention mechanism of connector B to the original condition.

|

Disconnect the instrument panel wire connector from the spiral cable.

Check for short to B+ in the circuit.

Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

Turn the ignition switch on.

Measure the voltage.

- Standard voltage:

Tester Connection Switch Condition Specified Condition D18-1 (D+) -

Body groundIgnition switch ON Below 1 V D18-2 (D-) -

Body groundIgnition switch ON Below 1 V

Check for open in the circuit.

Turn the ignition switch off.

Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

Measure the resistance.

- Standard resistance:

Tester Connection Condition Specified Condition D18-1 (D+) - D18-2 (D-) Always Below 1 Ω

Check for short to ground in the circuit.

Measure the resistance.

- Standard resistance:

Tester Connection Condition Specified Condition D18-1 (D+) -

Body groundAlways 1 MΩ or higher D18-2 (D-) -

Body groundAlways 1 MΩ or higher

Check for short in the circuit.

Release the activation prevention mechanism built into connector B (Click here).

Measure the resistance.

- Standard resistance:

Tester Connection Condition Specified Condition D18-1 (D+) - D18-2 (D-) Always 1 MΩ or higher

|

| ||||

| OK | |

| 6.CHECK SPIRAL CABLE |

Check for short to B+ in the circuit.

Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

Turn the ignition switch on.

Measure the voltage.

- Standard voltage:

Tester Connection Switch Condition Specified Condition W1-1 (D+) - Body ground Ignition switch ON Below 1 V W1-2 (D-) - Body ground Ignition switch ON Below 1 V

|

Check for open in the circuit.

Turn the ignition switch off.

Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

Measure the resistance.

- Standard resistance:

Tester Connection Condition Specified Condition W1-1 (D+) - W1-2 (D-) Always Below 1 Ω

Check for short to ground in the circuit.

Measure the resistance.

- Standard resistance:

Tester Connection Condition Specified Condition W1-1 (D+) - Body ground Always 1 MΩ or higher W1-2 (D-) - Body ground Always 1 MΩ or higher

Check for short in the circuit.

Release the activation prevention mechanism built into connector D (Click here).

Measure the resistance.

- Standard resistance:

Tester Connection Condition Specified Condition W1-1 (D+) - W1-2 (D-) Always 1 MΩ or higher

|

| ||||

| OK | ||

| ||