ENGINE UNIT (for Hatchback) > DISASSEMBLY |

for Preparation Click here

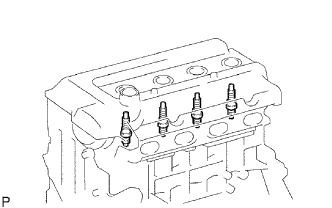

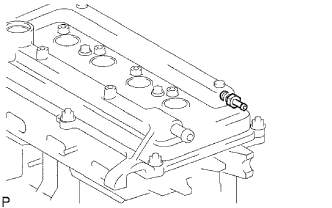

| 1. REMOVE SPARK PLUG |

Using a 16 mm spark plug wrench, remove the 4 spark plugs.

|

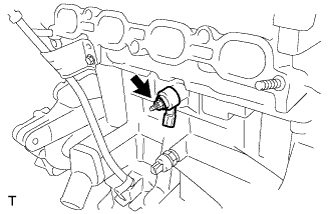

| 2. REMOVE KNOCK SENSOR |

Remove the nut and the knock sensor.

|

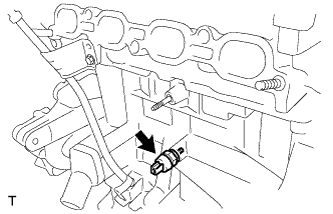

| 3. REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY |

Using a 24 mm deep socket wrench, remove the engine oil pressure switch.

|

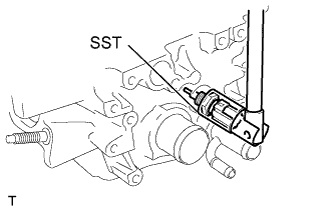

| 4. REMOVE ENGINE COOLANT TEMPERATURE SENSOR |

Using a 19 mm deep socket wrench, remove the engine coolant temperature sensor.

|

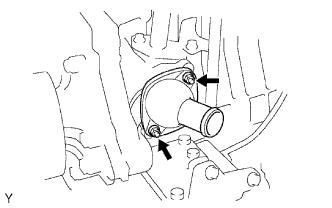

| 5. REMOVE WATER INLET |

Remove the 2 nuts and the water inlet.

|

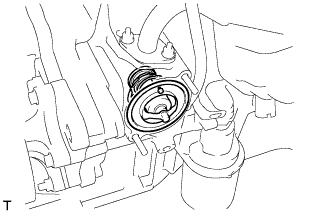

| 6. REMOVE THERMOSTAT |

|

Remove the thermostat from the cylinder block.

Remove the gasket from the thermostat.

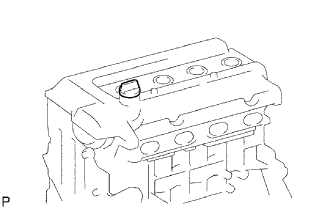

| 7. REMOVE OIL FILLER CAP SUB-ASSEMBLY |

|

Remove the oil filler cap from the cylinder head cover.

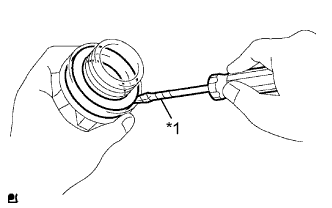

| 8. REMOVE OIL FILLER CAP GASKET |

Using a screwdriver with its tip wrapped in protective tape, remove the oil filler gasket from the oil filler cap.

Text in Illustration *1 Protective Tape

|

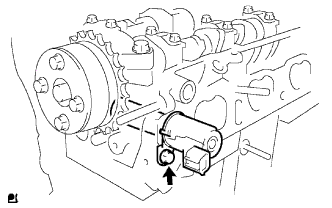

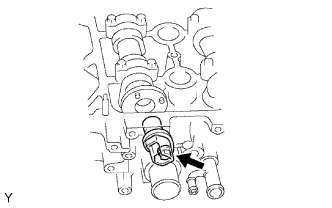

| 9. REMOVE CRANKSHAFT POSITION SENSOR |

Remove the bolt and the crankshaft position sensor.

| 10. REMOVE VENTILATION VALVE SUB-ASSEMBLY |

Remove the ventilation valve from the cylinder head cover.

|

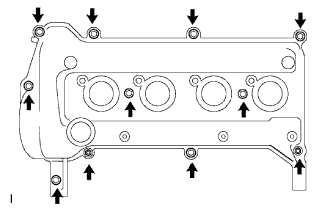

| 11. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY |

Remove the 9 bolts, 2 nuts and 2 seal washers and then remove the cylinder head cover.

|

Remove the gasket from the cylinder head cover.

| 12. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

Remove the bolt and the camshaft timing oil control valve.

|

| 13. REMOVE OIL LEVEL DIPSTICK GUIDE |

Remove the bolt and the oil level dipstick guide.

Remove the O-ring from the oil level dipstick guide.

| 14. REMOVE WATER PUMP PULLEY |

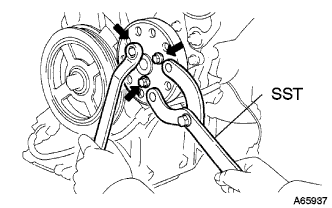

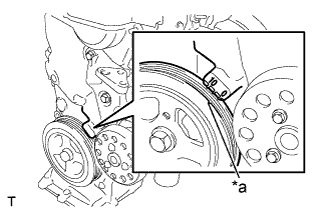

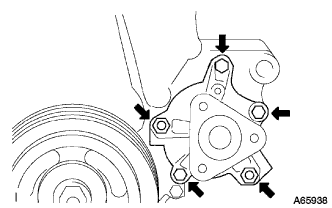

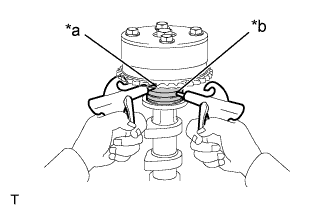

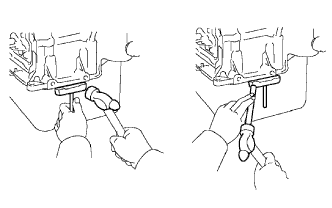

|

Using SST, hold the water pump pulley.

- SST

- 09960-10010

(09962-01000, 09963-00700)

Remove the 3 bolts and the water pump pulley.

| 15. REMOVE CRANKSHAFT DAMPER SUB-ASSEMBLY |

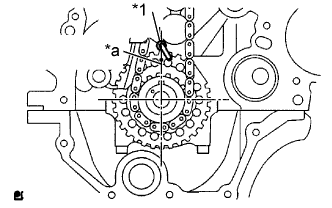

Set the No. 1 cylinder to TDC/compression.

Turn the crankshaft damper, and align its timing notch with timing mark "0" of the oil pump.

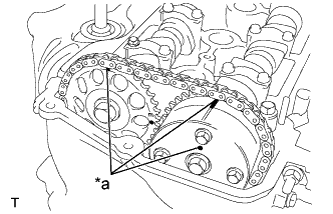

Text in Illustration *a Timing Notch Check that the timing marks on the camshaft timing sprocket and the camshaft timing gear are all facing upward, as shown in the illustration.

If not, turn the crankshaft 1 complete revolution (360°) and align the marks as above.Text in Illustration *a Timing Mark

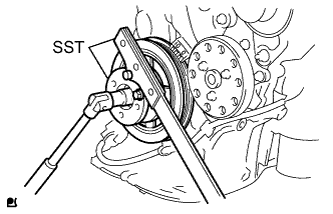

Using SST, loosen the bolt while holding the crankshaft damper.

- SST

- 09213-14010

(91651-60865)

09330-00021

- NOTICE:

- Check the SST installation positions when installing them, to avoid the SST fixing bolts from coming into contact with the oil pump assembly.

|

Remove the SST.

Remove the bolt and the crankshaft damper.

| 16. REMOVE TRANSVERSE ENGINE ENGINE MOUNTING BRACKET |

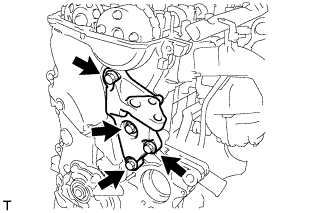

|

Remove the 4 bolts and the transverse engine engine mounting bracket.

| 17. REMOVE ENGINE WATER PUMP ASSEMBLY |

|

Remove the 3 bolts, 2 nuts the water pump assembly and water pump gasket.

| 18. REMOVE OIL PUMP ASSEMBLY |

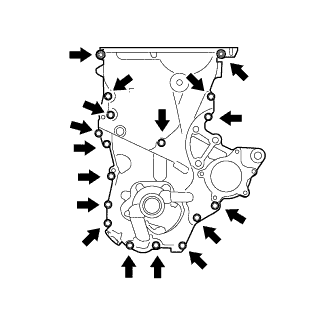

|

Remove the 16 bolts and the nut from the oil pump assembly.

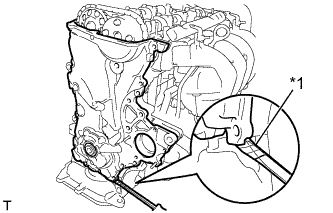

Using a screwdriver with its tip wrapped in protective tape, remove the oil pump assembly by prying between the cylinder head sub-assembly and cylinder block sub-assembly.

Text in Illustration *1 Protective Tape - NOTICE:

- Do not damage the contact surfaces of the oil pump assembly and oil pan sub-assembly.

|

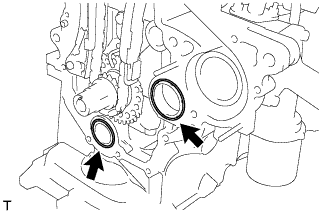

Remove the 2 O-rings from the cylinder block sub-assembly and the oil pan sub-assembly.

|

| 19. REMOVE OIL PUMP SEAL |

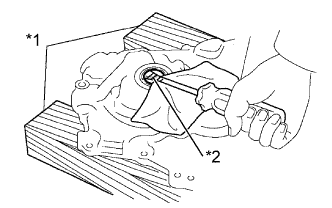

Using a screwdriver with its tip wrapped in protective tape, remove the oil pump seal.

Text in Illustration *1 Wooden Block *2 Protective Tape

|

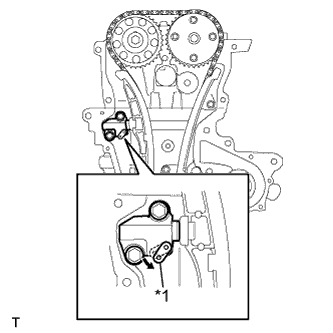

| 20. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY |

|

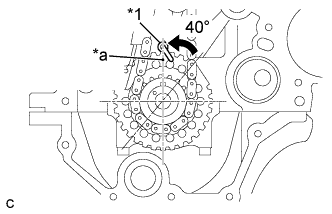

- NOTICE:

- Do not rotate the crankshaft with the chain tensioner removed.

- When rotating the camshaft with the timing chain removed, rotate the crankshaft counterclockwise 40° from the TDC first, and align the oil jet hole with the paint mark. This prevents the pistons from coming into contact with the valves.

| *1 | Oil Jet |

| *a | Timing Mark (1 dot) |

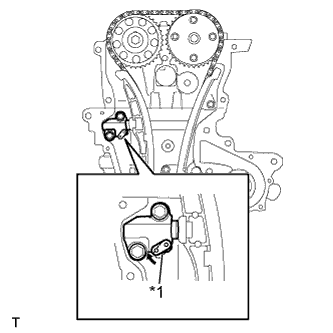

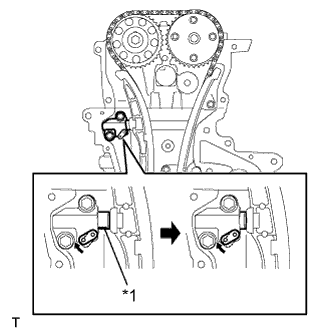

Pull up the stopper plate and hold it with its lock released.

Text in Illustration *1 Stopper Plate

|

Unlock the plunger of the tensioner and push it in to the end.

Text in Illustration *1 Plunger

|

Pull down the stopper plate with the plunger pushed to the end and lock the plunger.

Text in Illustration *1 Stopper Plate

|

Insert a 3 mm (0.12 in.) diameter bar into the hole in the stopper plate and lock the plunger.

|

Remove the 2 bolts and the No. 1 chain tensioner.

|

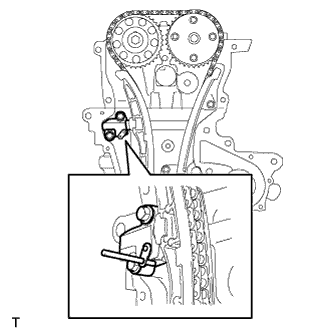

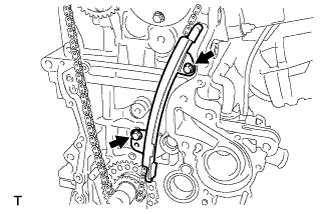

| 21. REMOVE CHAIN TENSIONER SLIPPER |

Remove the chain tensioner slipper.

|

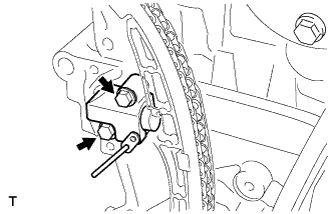

| 22. REMOVE NO. 1 CHAIN VIBRATION DAMPER |

Remove the 2 bolts and the No. 1 chain vibration damper.

|

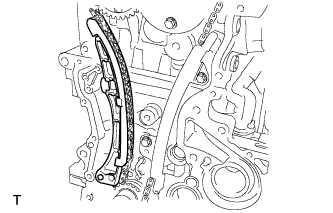

| 23. REMOVE CHAIN SUB-ASSEMBLY |

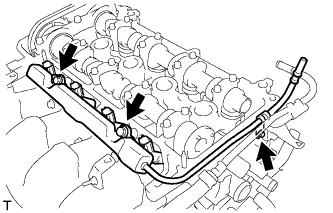

| 24. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY |

Remove the 3 bolts and the fuel delivery pipe sub-assembly with 4 fuel injectors.

- NOTICE:

- Do not drop the fuel injectors when removing the fuel delivery pipe sub-assembly.

|

| 25. REMOVE NO. 1 DELIVERY PIPE SPACER |

|

Remove the 2 No. 1 delivery pipe spacers.

| 26. REMOVE INJECTOR VIBRATION INSULATOR |

|

Remove the 4 injector vibration insulators.

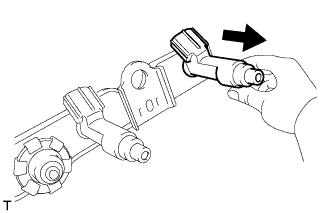

| 27. REMOVE FUEL INJECTOR ASSEMBLY |

Pull the 4 fuel injector assemblies out of the fuel delivery pipe sub-assembly.

- NOTICE:

- If a component has been dropped or subjected to a strong impact, replace it.

Text in Illustration

Pull

|

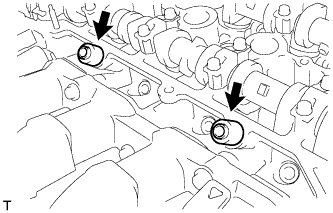

| 28. REMOVE CAMSHAFT POSITION SENSOR |

Remove the bolt and the camshaft position sensor.

|

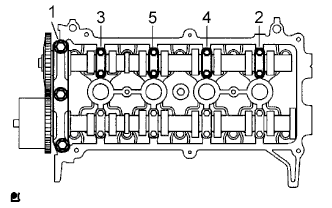

| 29. REMOVE NO. 2 CAMSHAFT |

|

- NOTICE:

- Do not rotate the crankshaft with the chain tensioner removed.

- When rotating the camshaft with the timing chain removed, rotate the crankshaft counterclockwise 40° from the TDC first, and align the oil jet hole with the paint mark. This prevents the pistons from coming into contact with the valves.

| *1 | Oil Jet |

| *a | Timing Mark (1 dot) |

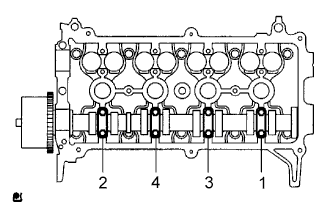

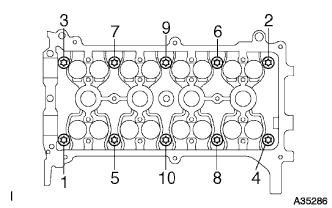

Using several steps, loosen and remove the 11 bearing cap bolts uniformly in the sequence shown in the illustration, then remove the No. 1 camshaft bearing cap, No. 2 camshaft bearing cap and No. 2 camshaft.

- NOTICE:

- Loosen each bolt uniformly while keeping the camshaft level.

|

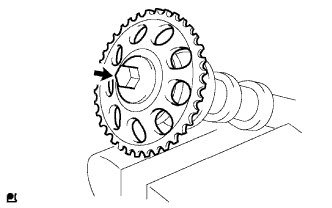

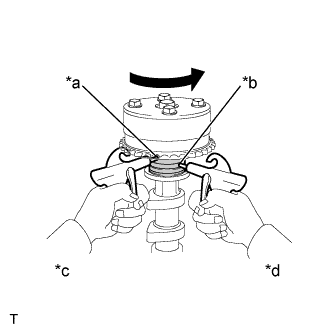

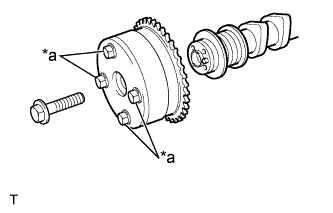

| 30. REMOVE CAMSHAFT TIMING SPROCKET |

Clamp the camshaft in a vise, and confirm that it is locked.

- NOTICE:

- Do not damage the camshaft.

|

Remove the bolt and the camshaft timing sprocket.

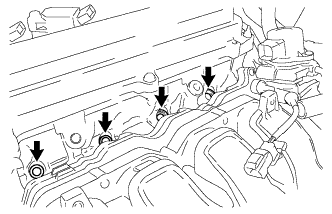

| 31. REMOVE CAMSHAFT |

Using several steps, loosen and remove the 8 bearing cap bolts uniformly in the sequence shown in the illustration, then remove the No. 2 camshaft bearing cap and the camshaft.

- NOTICE:

- Loosen each bolt uniformly keeping the camshaft level.

|

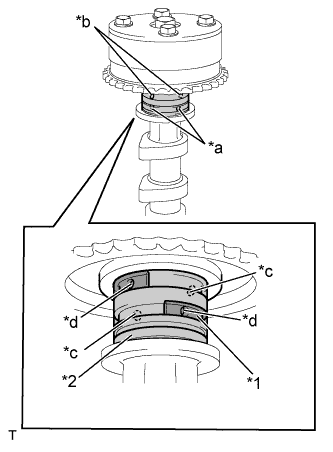

| 32. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY |

Clamp the camshaft in a vise, and confirm that it is locked.

- NOTICE:

- Do not damage the camshaft.

Cover the 4 oil paths of the cam journal with tape as shown in the illustration.

Text in Illustration *1 Rubber Piece *2 Vinyl Tape *a Advance Side Paths *b Retard Side Paths *c Open *d Closed - HINT:

- One of the 2 grooves located on the cam journal is for retarding cam timing (upper) and the other is for advancing cam timing (lower). Each groove has 2 oil paths. Plug one of the oil paths for each groove with a piece rubber before wrapping the cam journal with the tape.

|

Puncture the tape covering the advance oil path and the retard oil path on the opposite side from the advance oil path.

Apply compressed air at about 150 kPa (1.5 kgf/cm2) pressure into the 2 broken paths (the advance side path and the retard side path).

Text in Illustration *a Retard Side Paths *b Advance Side Paths - NOTICE:

- Cover the paths with a piece of cloth to prevent oil splashes.

|

Confirm that the camshaft timing gear revolves in the timing advance direction when the air pressure on the timing retard path is reduced.

Text in Illustration *a Retard Side Paths *b Advance Side Paths *c Decompress *d Hold Pressure - HINT:

- The lock pin is released and the camshaft timing gear revolves in the advance direction.

|

When the camshaft timing gear reaches the most advanced position, release the air pressure on the timing retard side path, and then release the air pressure on the timing advance side path.

- NOTICE:

- Camshaft timing gear occasionally shifts to the retard side abruptly if the air pressure on the advance side path is released first. It often results in the breakage of the lock pin.

Remove the bolt and the camshaft timing gear.

Text in Illustration *a Do not remove - NOTICE:

- Do not remove the other 4 bolts.

- When reusing the camshaft timing gear, unlock the lock pin inside the camshaft timing gear first.

|

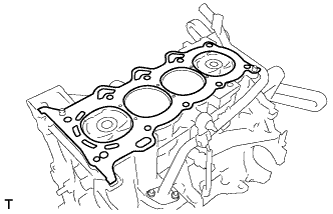

| 33. REMOVE CYLINDER HEAD SUB-ASSEMBLY |

|

Using several steps, uniformly loosen and remove the 10 cylinder head bolts with an 8 mm bi-hexagon wrench in the sequence shown in the illustration. Remove the 10 plate washers.

- NOTICE:

- Do not drop the washers into the cylinder head.

- Head warpage or cracking could result from removing the bolts in the wrong order.

| 34. REMOVE CYLINDER HEAD GASKET |

|

Remove the cylinder head gasket.

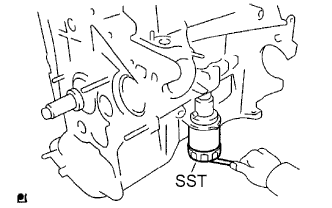

| 35. REMOVE OIL FILTER SUB-ASSEMBLY |

Using SST, remove the oil filter.

- SST

- 09228-06501

|

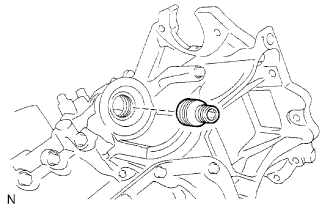

| 36. REMOVE OIL FILTER UNION |

Using a 12 mm hexagon wrench, remove the oil filter union.

|

| 37. REMOVE REAR ENGINE OIL SEAL |

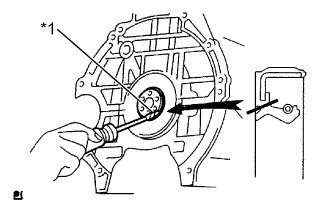

Using a knife, cut off the rear engine oil seal lip.

Text in Illustration *1 Protective Tape

|

Using a screwdriver with its tip wrapped in protective tape, pry out the rear engine oil seal.

- NOTICE:

- After removal, check the crankshaft for any damage. If damaged, smooth the surface with 400-grit sandpaper.

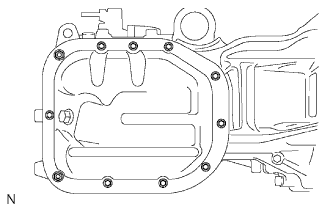

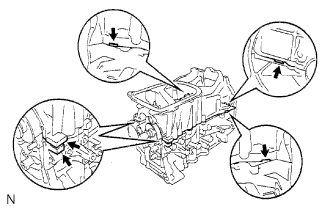

| 38. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY |

Remove the drain plug and gasket.

Remove the 9 bolts and 2 nuts.

|

Insert the blade of oil pan seal cutter between the No. 1 oil pan and No. 2 oil pan, and cut off the applied sealer and remove No. 2 oil pan.

- NOTICE:

- Be careful not to damage the contact surfaces of the oil pan.

|

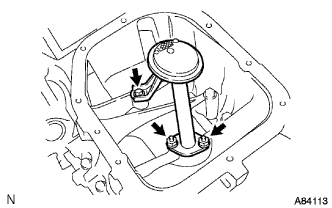

| 39. REMOVE OIL STRAINER SUB-ASSEMBLY |

|

Remove the bolt and 2 nuts.

Remove the oil strainer and the gasket.

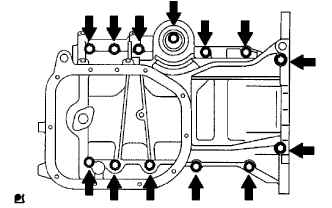

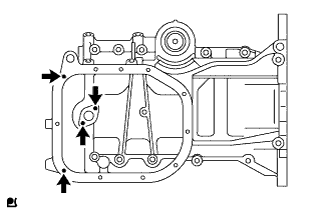

| 40. REMOVE OIL PAN SUB-ASSEMBLY |

Loosen and remove the 13 bolts uniformly in several steps.

|

Using a screwdriver, remove the No. 1 oil pan by prying between the cylinder block and No. 1 oil pan.

- NOTICE:

- Be careful not to damage the contact surfaces of the oil pan.

|

Remove the 2 O-rings from the cylinder block.

| 41. REMOVE STUD BOLT |

|

Using "TORX" socket wrench E5, remove the 4 stud bolts.